Soy Based Prebiotic, Probiotic and Synbiotic Vegan Chocolate

These advanced process technologies constitute a significant advancement in the development of bio-functional, vegan-friendly chocolates, effectively integrating scientifically supported health benefits with premium sensory indulgence. Through the integration of scientifically proven nutritional elements into plant-based chocolate recipes, these technologies craft chocolates that captivate both wellness-driven consumers and lovers of classic indulgence. Prebiotic Milk Chocolates – Formulated with prebiotic fibers that support gut health by promoting the growth of beneficial microorganisms, while maintaining the smooth texture and rich flavor of milk chocolate. Probiotic Milk Chocolates – Enriched with live, beneficial probiotic cultures that contribute to improved digestive and immune health, without compromising the sensory quality of the chocolate. Synbiotic Milk Chocolates – A synergistic blend of both probiotics and prebiotics, designed to maximize gut-health benefits through enhanced microbial balance, delivered in a delicious, vegan-friendly chocolate format.

Soy Based Multifunctional Probiotic Milk Powder

The developed process technology for soy-based probiotic milk powder focuses on creating a stable, nutritious, and sensory-acceptable plant-based beverage enriched with beneficial probiotic cultures. This technology optimizes soy extraction, fermentation parameters, and culture incorporation to ensure high probiotic viability throughout processing and storage. It also addresses challenges related to flavor refinement and product stability, resulting in a lactose-free, vegan-friendly functional beverage that supports digestive wellness while meeting modern consumer demand for healthy, plant-derived alternatives. Probiotics were added to soy based milk based medium, and their physicochemical and sensory qualities, as well as probiotic viability, were studied during storage. When compared to control milk powder and soymilk powder, the addition of potential probiotics did not affect the physicochemical qualities.

.jpg)

Process Technology for Dietary Fibre Extraction from Soybean and Chickpea Hulls

The process technology for producing dietary fibre from soybean and chickpea hulls enables the conversion of low-value agro- processing residues into a high-quality, food-grade ingredient. The extracted fibre contains around 88% total dietary fibre and exhibits desirable functional attributes such as water and oil absorption, neutral flavour, and light colour, making it suitable for a wide range of health-oriented food applications. This technology supports clean-label product development and contributes to sustainable utilization of by-products, promoting circular bio-economy principles. The process has been validated at pilot scale and successfully commercialized, demonstrating its readiness for industrial adoption. The dietary fibre can be incorporated into functional food formulations, nutraceutical blends, baked foods, snacks, beverages, and fibre- enriched products. By offering a cost-effective, plant-based ingredient with excellent nutritional and functional properties, the technology provides new opportunities for food industries, start-ups, and entrepreneurs while simultaneously reducing waste and enhancing value addition in soybean and chickpea processing

Soy Chaap

Soy chaap offers great potential for developing value-added and affordable protein-rich functional food products. It will provide a quality protein at a low cost with good sensory characteristics. The process technology of soy-based food product "Soy Chaap" with high protein content has been developed by ICAR-CIAE. Other salient features of soy chaap are cholesterol free, no preservatives, easy to cook, low cost of production, and high sensory acceptability. The developed product can be stored up to 28 days and 3 days under freezing condition and refrigerated condition, respectively.

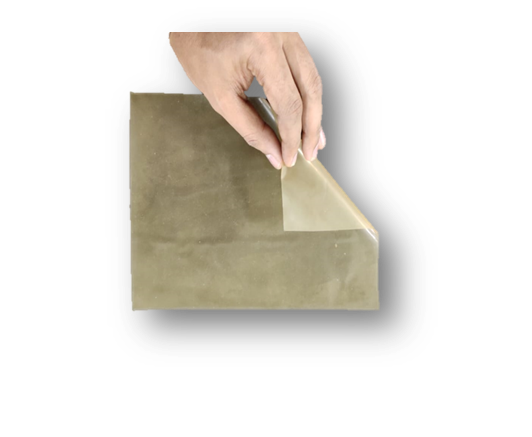

Soybean Aqueous Extract-Based Edible Film

The soybean aqueous extract based edible film technology provides a biodegradable and eco-friendly alternative to conventional plastic packaging for food applications. The film produced from this natural matrix offers good flexibility, transparency, and barrier properties, making it suitable for direct contact with a variety of food products. The material has been successfully evaluated for wrapping muffins and cheese, demonstrating its potential use in soft bakery items, dairy products, and other moisture-sensitive foods. Its clean-label composition, safety, and biodegradability align with current global priorities for sustainable packaging and reduced plastic dependency. This technology offers opportunities for industries, start-ups, and MSMEs to introduce innovative packaging formats such as edible films, eco-friendly wrappers, and protective coatings for fresh produce.